stainless steel pricelist

Home

Home- · door seal strip 3m exporter

- · thick door seal strip company

- · gasket seal strip exporters

- · ce cetification front door seal strip

- · led neon moon light supplier

- · led neon ribbon light product

- · pvc white board profile service

- · bathtub seal strip pricelist

- · sponge seal service

- · felt window seal strip suppliers

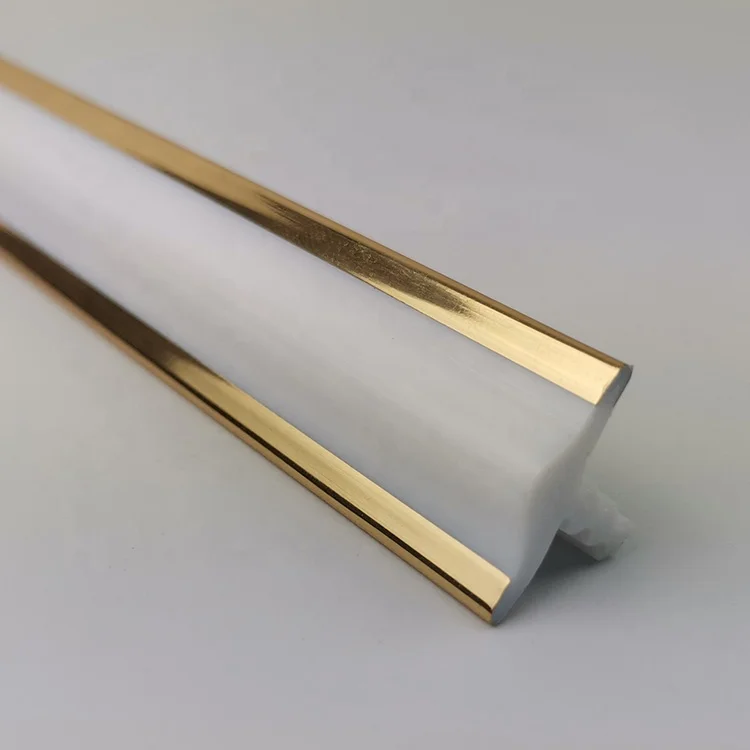

In kitchens, they can be used for backsplashes or cabinet doors, introducing a pop of color without overwhelming the space In kitchens, they can be used for backsplashes or cabinet doors, introducing a pop of color without overwhelming the space

In kitchens, they can be used for backsplashes or cabinet doors, introducing a pop of color without overwhelming the space In kitchens, they can be used for backsplashes or cabinet doors, introducing a pop of color without overwhelming the space

Some suppliers offer package deals that include installation, which can simplify the process and sometimes lead to overall cost savings Some suppliers offer package deals that include installation, which can simplify the process and sometimes lead to overall cost savings

Some suppliers offer package deals that include installation, which can simplify the process and sometimes lead to overall cost savings Some suppliers offer package deals that include installation, which can simplify the process and sometimes lead to overall cost savings

Its versatility also extends to color options, with a range of colors available to suit any taste and decor scheme Its versatility also extends to color options, with a range of colors available to suit any taste and decor scheme

Its versatility also extends to color options, with a range of colors available to suit any taste and decor scheme Its versatility also extends to color options, with a range of colors available to suit any taste and decor scheme